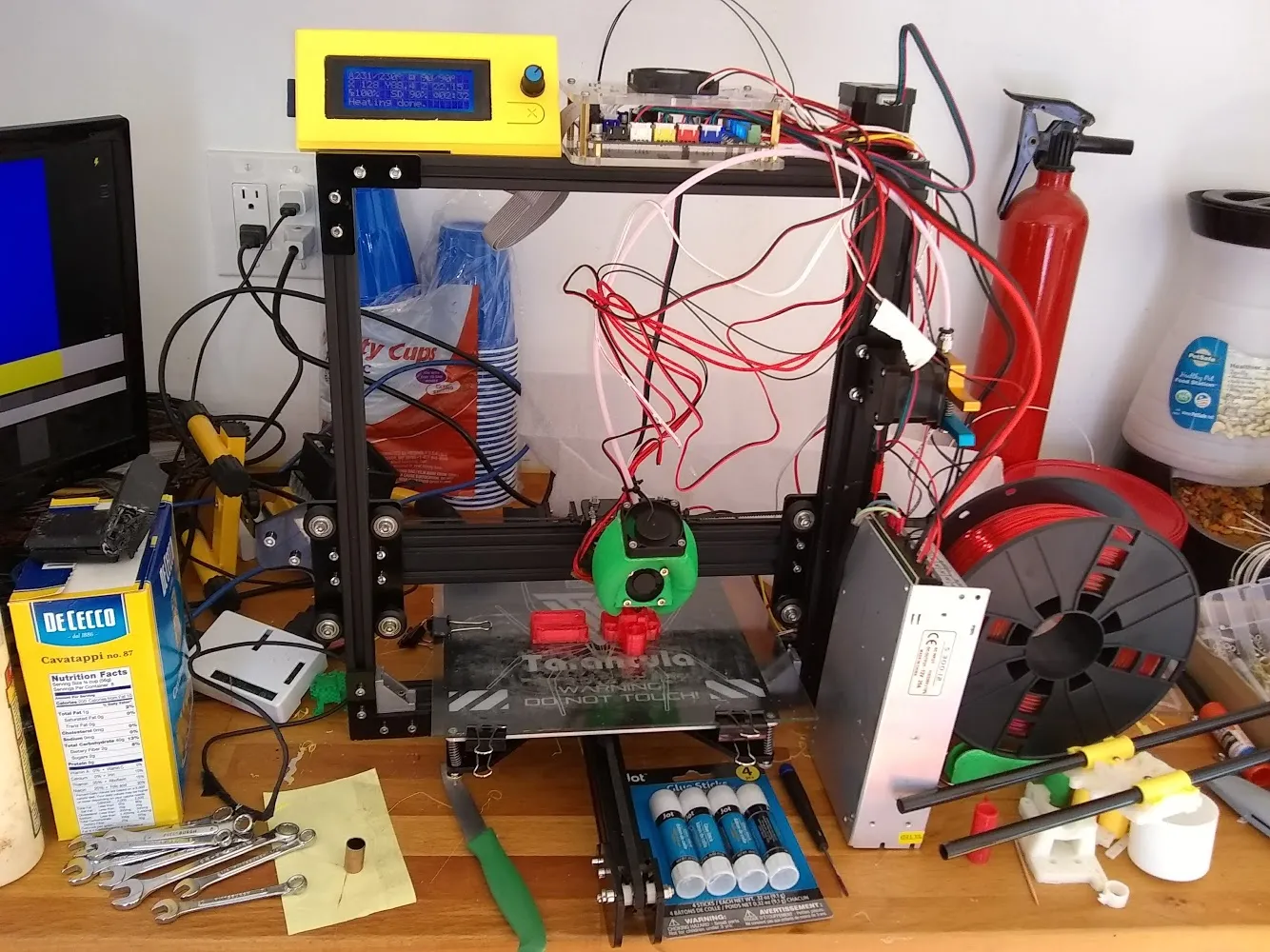

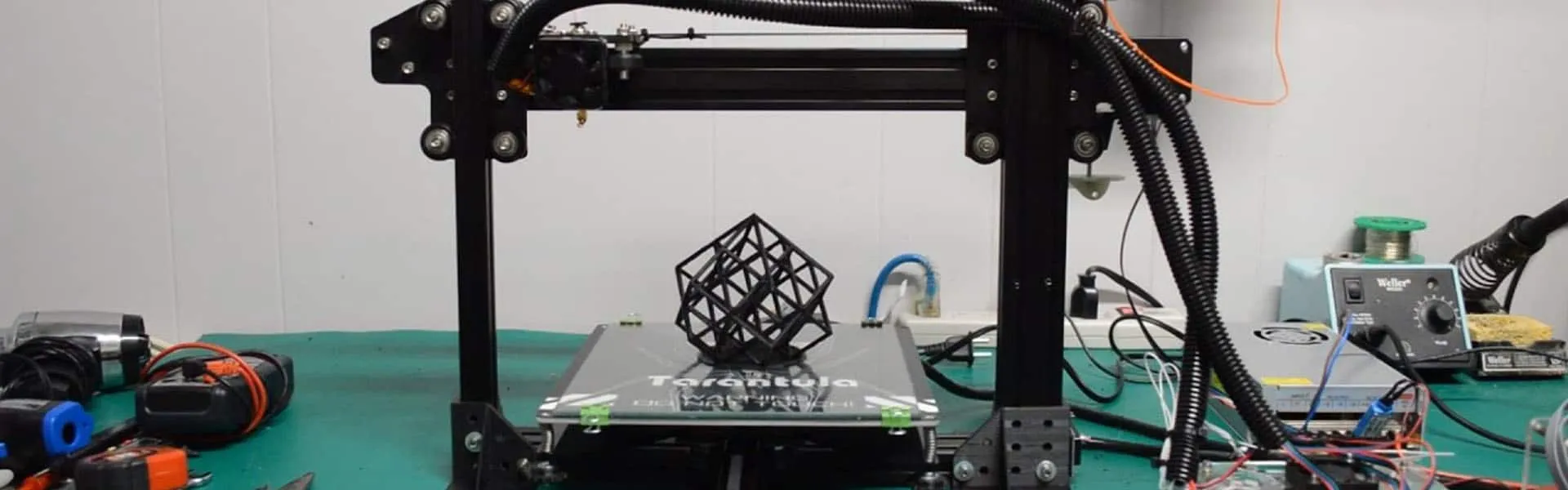

What is the Tevo Tarantula 3D Printer?

The Tevo Tarantula is a popular and affordable 3D printer, known for its ease of assembly and large print volume relative to its price point. It quickly gained traction in the 3D printing community as a go-to option for beginners and hobbyists looking to enter the world of additive manufacturing without breaking the bank. Its open-frame design and modular construction make it relatively easy to modify and upgrade, leading to a thriving community of users who share tips, designs, and modifications. Despite its affordability, the Tevo Tarantula provides a solid foundation for creating a wide range of 3D printed objects, from functional parts to artistic creations. Many users find its open-source nature appealing, allowing for customization and experimentation.

Why Upgrade Your Tevo Tarantula?

Upgrading your Tevo Tarantula can significantly improve print quality, reliability, and overall user experience. While the printer offers a good starting point, certain components can be improved to enhance its performance. Upgrades can address common issues such as bed leveling, extruder performance, and frame stability, leading to more accurate and consistent prints. Additionally, upgrades can introduce new features, such as filament runout detection or automatic bed leveling, which further streamline the printing process. Furthermore, upgrading allows users to personalize their printer and tailor it to their specific needs and printing preferences. This level of customization is one of the most appealing aspects of owning a Tevo Tarantula and is what makes it so popular within the community.

Top 7 Upgrades for Your Tevo Tarantula

Here are seven key upgrades that can enhance your Tevo Tarantula 3D printer, improving print quality, reliability, and usability.

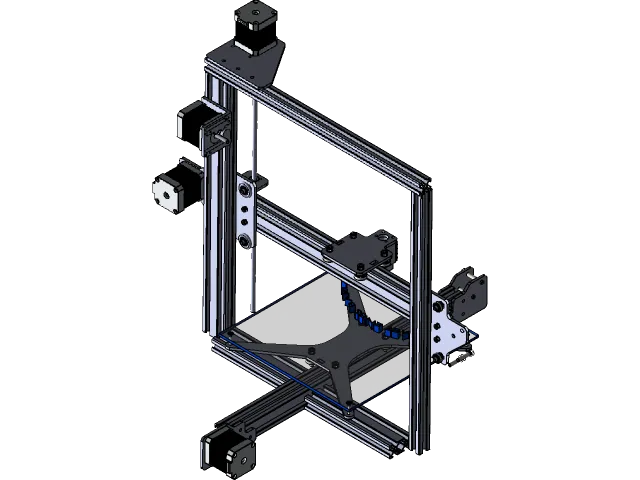

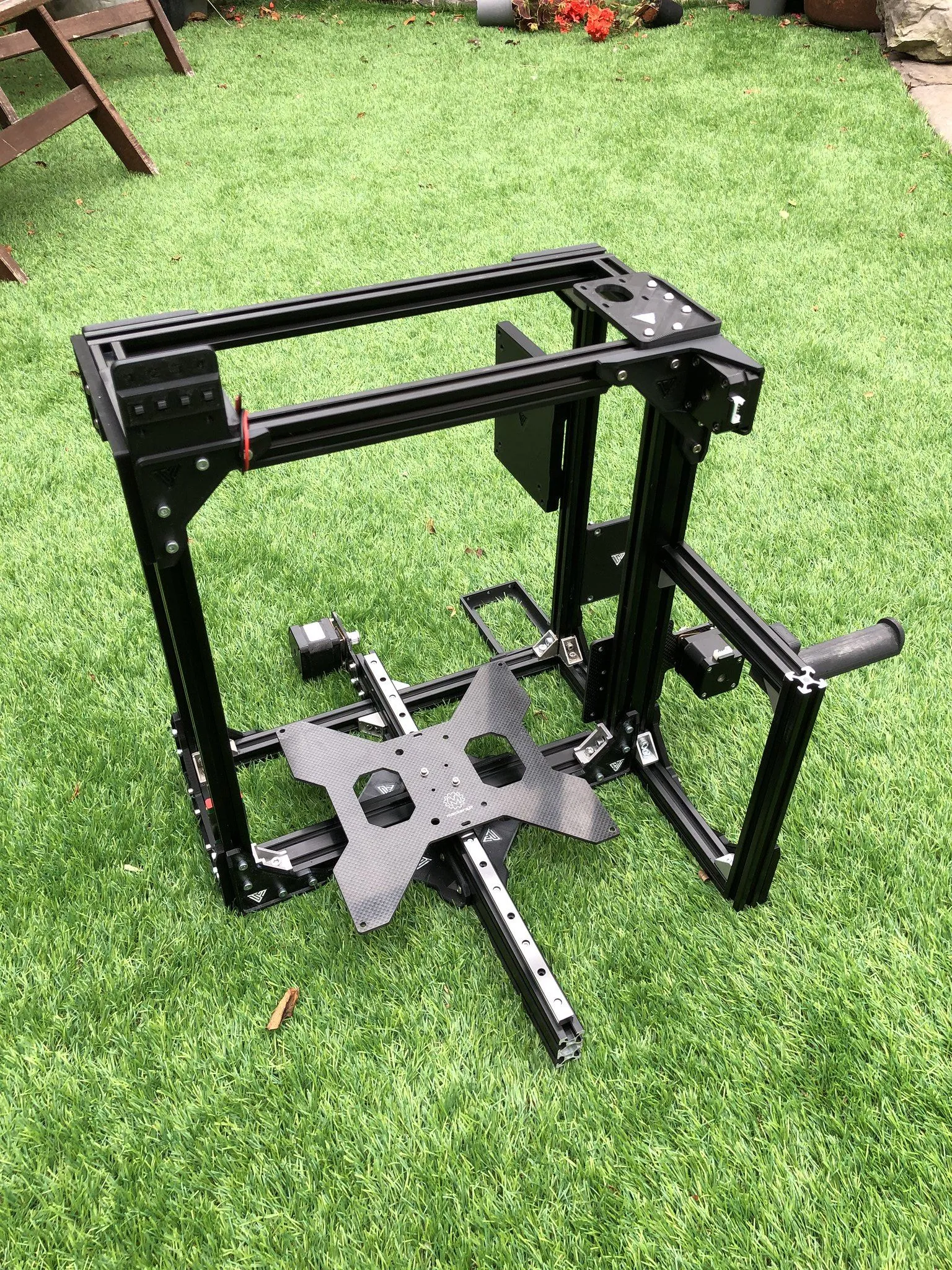

Upgrade 1: Sturdy Frame Enhancement

A stable frame is essential for accurate 3D printing. The Tevo Tarantula’s original frame can be prone to flex and wobble, especially during fast movements. Upgrading the frame can dramatically improve print quality by reducing vibrations and ensuring consistent layer adhesion. This upgrade typically involves reinforcing or replacing the existing frame components to provide a more rigid structure. Several options exist, ranging from simple reinforcement brackets to complete frame replacements made from more robust materials.

Benefits of a Sturdy Frame

A sturdy frame minimizes vibrations and improves overall print quality. It allows for more precise movements and reduces the likelihood of print failures caused by frame flex. This leads to better layer adhesion, sharper details, and a more consistent print surface. It also reduces noise during printing, making the printer more pleasant to operate. Moreover, a stable frame extends the lifespan of other printer components by reducing stress and wear.

Materials for Frame Upgrade

Common materials for frame upgrades include aluminum extrusion, steel rods, and printed reinforcement parts. Aluminum extrusion provides a good balance of strength and weight and is easy to work with. Steel rods offer excellent rigidity, while printed parts can be customized to fit specific needs. The choice of material depends on the desired level of rigidity, budget, and the complexity of the upgrade. It is critical to select materials that are structurally sound and well-suited for the printer’s operational environment.

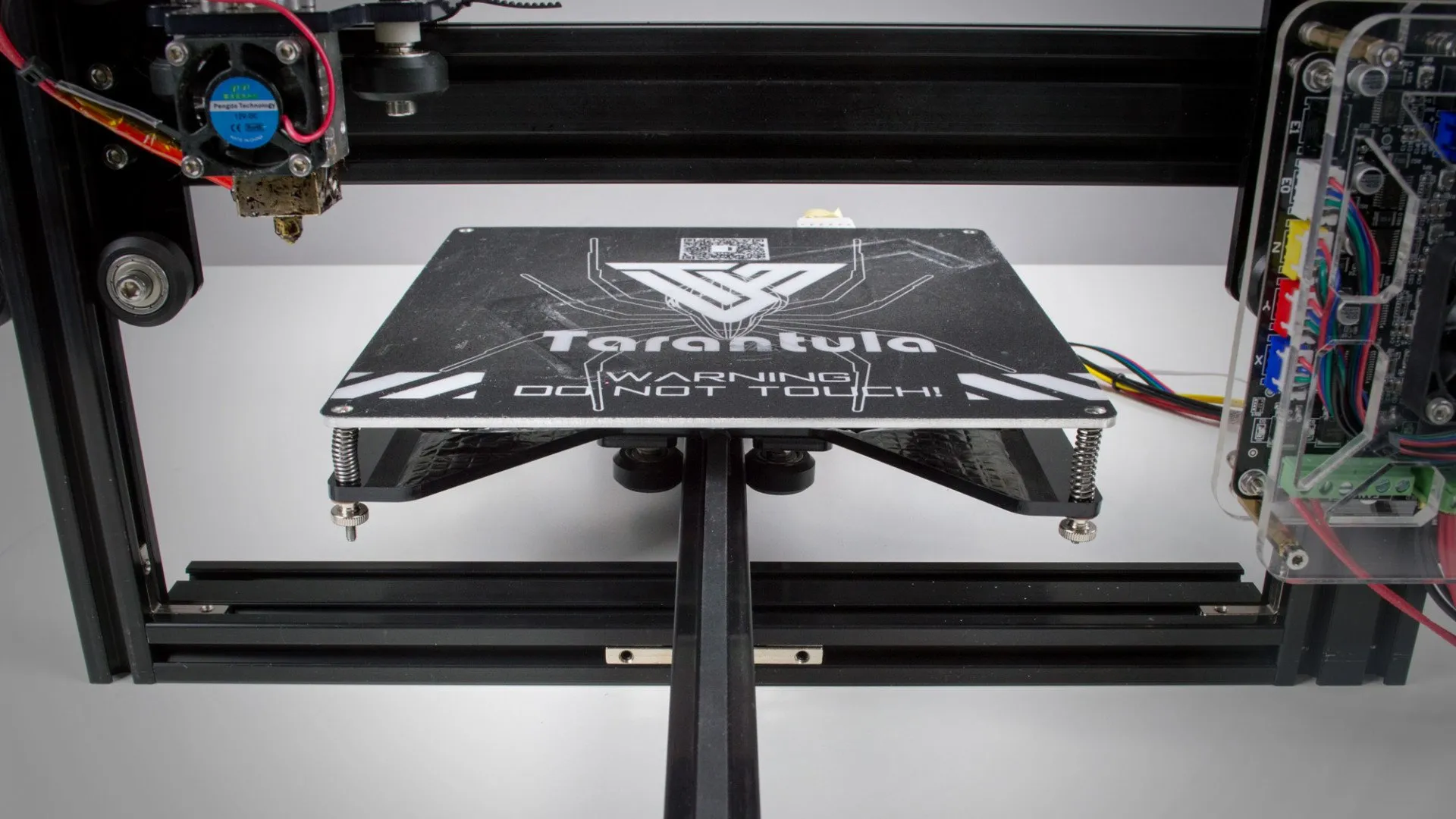

Upgrade 2: Heated Bed Improvements

The heated bed is crucial for ensuring proper adhesion of the first layer to the print surface and preventing warping. The original heated bed on the Tevo Tarantula may not provide even heating, especially towards the edges. Upgrading to a higher-quality heated bed or adding insulation can improve heat distribution and reduce the risk of print failures. This typically involves replacing the bed or adding a thermal insulator underneath to maintain consistent temperatures.

Importance of a Good Heated Bed

A well-functioning heated bed is critical for successful 3D printing, especially when using materials like ABS or PETG. It ensures that the first layer adheres properly to the build surface, preventing warping and lifting. Consistent heating across the entire bed surface is crucial for consistent print quality. A good heated bed also helps to reduce the environmental effects on the print by maintaining a stable temperature throughout the printing process.

Heated Bed Options

Options include replacing the bed with a more powerful one or adding insulation to the existing bed. Upgrading to a bed with a silicone heater can provide more uniform heating. Adding a layer of insulation, such as cork or a thermal pad, underneath the bed can help retain heat and improve energy efficiency. Consider adding a glass or PEI sheet for better print adhesion and a smoother finish.

Upgrade 3: Extruder System Upgrade

The extruder is responsible for feeding the filament into the hot end, where it is melted and extruded onto the print bed. The original extruder on the Tevo Tarantula can sometimes struggle with certain filaments or may not be as reliable as higher-end options. Upgrading the extruder can improve filament feeding, reduce jamming, and allow for printing with a wider range of materials.

Understanding Extruders

There are two main types of extruders: direct drive and Bowden. Direct drive extruders are mounted directly on the hot end, providing more precise filament control but adding weight to the print head. Bowden extruders have the extruder motor separate from the hot end, reducing weight on the print head but potentially requiring more tuning. Both types have their advantages and disadvantages.

Extruder Upgrade Choices

Popular upgrades include replacing the stock extruder with a geared extruder for improved filament grip and feeding. Consider a dual-gear extruder for enhanced reliability. Upgrading to a direct-drive system can also provide better control, especially for flexible filaments. Ensure the chosen extruder is compatible with the hot end and other components of your Tevo Tarantula.

Upgrade 4: Firmware Updates and Tuning

Firmware controls the printer’s movements and settings. Updating the firmware can improve performance, add new features, and fix bugs. Tuning the printer’s settings, such as acceleration, jerk, and steps/mm, can further optimize print quality. Regular updates are essential for maximizing the printer’s capabilities and resolving potential issues.

Benefits of Up-to-date Firmware

Updated firmware can bring new features, bug fixes, and performance improvements. It can enhance print quality, improve stability, and optimize the printer’s performance with different materials. Firmware updates are often released to address any identified shortcomings in the original software and to keep the printer running smoothly.

Firmware Update Process

The process typically involves downloading the firmware from the manufacturer or a community-supported source, flashing it onto the printer’s control board via a USB connection. Always back up your existing settings before updating the firmware. Follow the instructions provided by the firmware developer carefully to avoid bricking your printer.

Upgrade 5: Belt Tensioners

Loose belts can lead to print quality issues, such as ghosting and inaccurate dimensions. Adding belt tensioners allows you to easily adjust and maintain the tension of the belts, improving print accuracy and reducing vibrations. Belt tensioners ensure consistent and precise movement of the print head and bed.

Why Use Belt Tensioners?

Belt tensioners prevent the belts from becoming loose over time, which can cause inaccuracies in prints. Properly tensioned belts reduce vibrations and ensure the printer moves precisely along the X and Y axes. Consistent belt tension leads to better print quality and dimensional accuracy.

Belt Tensioner Types

There are various designs available, including screw-based and spring-loaded tensioners. Screw-based tensioners allow for precise adjustments, while spring-loaded tensioners automatically maintain tension. Choose the type that best suits your needs and ease of use. Ensure the tensioners are securely mounted to the printer frame.

Upgrade 6: Improved Nozzle & Hotend

The hotend is responsible for melting the filament and extruding it through the nozzle. Upgrading the hotend and nozzle can improve print quality, allow for higher printing temperatures, and increase the range of compatible filaments. A better hotend can handle a wider range of printing materials and printing speeds.

Nozzle and Hotend Considerations

Consider nozzle size and material. Smaller nozzles offer higher detail, while larger nozzles allow for faster printing. Different materials, such as hardened steel or stainless steel, are better suited for abrasive filaments. The hotend should be able to maintain consistent temperatures for optimal printing.

Nozzle and Hotend Upgrade Options

Popular upgrades include all-metal hotends for higher temperature resistance and improved thermal performance. Upgrading to a nozzle made of hardened steel or other wear-resistant materials can increase lifespan and is a must if printing with abrasive filaments. Replacing the stock heat break with a high-quality one can reduce clogging and improve print quality.

Upgrade 7: Filament Runout Sensor

A filament runout sensor detects when the filament has run out and pauses the print, preventing failed prints. This simple upgrade can save you time, filament, and frustration. It is an essential upgrade for anyone who wants to print unattended.

Advantages of a Filament Sensor

The primary advantage is preventing failed prints due to running out of filament mid-print. It allows for unattended printing, as the printer can pause and alert you when the filament is depleted. This saves filament, time, and effort, especially for long prints. It’s a cost-effective solution for ensuring that the printing process is not interrupted due to an empty spool.

Filament Sensor Installation Guide

The installation process involves mounting the sensor on the printer frame and connecting it to the control board. Detailed instructions are usually provided with the sensor. Ensure the sensor is correctly wired and configured in the firmware. Consult the printer’s documentation and online resources for specific installation guidance.

Conclusion

Upgrading your Tevo Tarantula can significantly improve its performance and reliability. From a sturdy frame to an improved extruder and heated bed, each upgrade contributes to better print quality and a more enjoyable printing experience. By carefully selecting and implementing these upgrades, you can transform your Tevo Tarantula into a high-performing 3D printer capable of producing impressive results. Remember to research each upgrade thoroughly, follow instructions carefully, and enjoy the process of enhancing your 3D printing capabilities.