Choosing the Right Acrylic Parts for Your Tevo Tarantula

Upgrading your Tevo Tarantula with acrylic parts offers a fantastic way to improve its aesthetics, stability, and overall performance. However, with a plethora of designs available, choosing the right parts can be a daunting task. Consider your specific needs and goals for the printer. Are you aiming for enhanced rigidity, better cable management, or simply a more visually appealing machine? Think about the areas where your printer currently struggles. Are there vibrations? Is the frame wobbly? Do you need better access to the electronics? Prioritize parts that address these issues. Also, assess the quality of the acrylic. Look for designs that utilize high-quality, laser-cut acrylic for durability and precision. Consider designs that are compatible with your existing upgrades. Make sure they align with your future plans for modifications. Finally, carefully read reviews and check community forums to understand the experiences of other users with the acrylic parts you are considering. This will give you insight into their ease of installation and overall effectiveness.

Why Acrylic is Ideal for 3D Printer Parts

Acrylic stands out as an excellent material for 3D printer parts, particularly for the Tevo Tarantula, for several compelling reasons. Firstly, its transparency allows for easy monitoring of the printing process, crucial for observing potential issues like layer adhesion or filament jams. Secondly, acrylic is significantly lighter than alternative materials like metal, reducing the overall weight of the printer and potentially improving its speed and responsiveness. Thirdly, acrylic possesses excellent rigidity and dimensional stability, resulting in minimal flex and warping, which translates to improved print quality and accuracy. Moreover, acrylic is relatively easy to work with. It can be readily laser-cut or 3D printed, offering a wide range of customization options. The material is also resistant to many common chemicals and solvents, ensuring it can withstand the rigors of the 3D printing environment. Ultimately, its combination of aesthetics, durability, and workability makes acrylic a preferred choice for enhancing the Tevo Tarantula’s functionality and visual appeal.

Benefits of Acrylic Parts for Tevo Tarantula

Acrylic parts for the Tevo Tarantula provide a host of benefits, enhancing both the printer’s performance and aesthetics. One primary advantage is the increased rigidity they offer. Acrylic frames and supports reduce vibrations and flexing, resulting in more precise and higher-quality prints. This is especially beneficial for intricate designs. Furthermore, acrylic parts often improve the printer’s visual appeal. The sleek, transparent nature of acrylic creates a modern and sophisticated look, transforming the somewhat industrial appearance of the original Tevo Tarantula. Another key benefit is the improved organization and accessibility. Acrylic enclosures and covers help with cable management. This makes it easier to maintain and troubleshoot your printer. Acrylic parts can also protect sensitive electronic components from dust and damage, prolonging the printer’s lifespan. Acrylic is easily customizable, allowing you to create personalized upgrades tailored to your specific printing needs. This level of customization is difficult to achieve with the original parts.

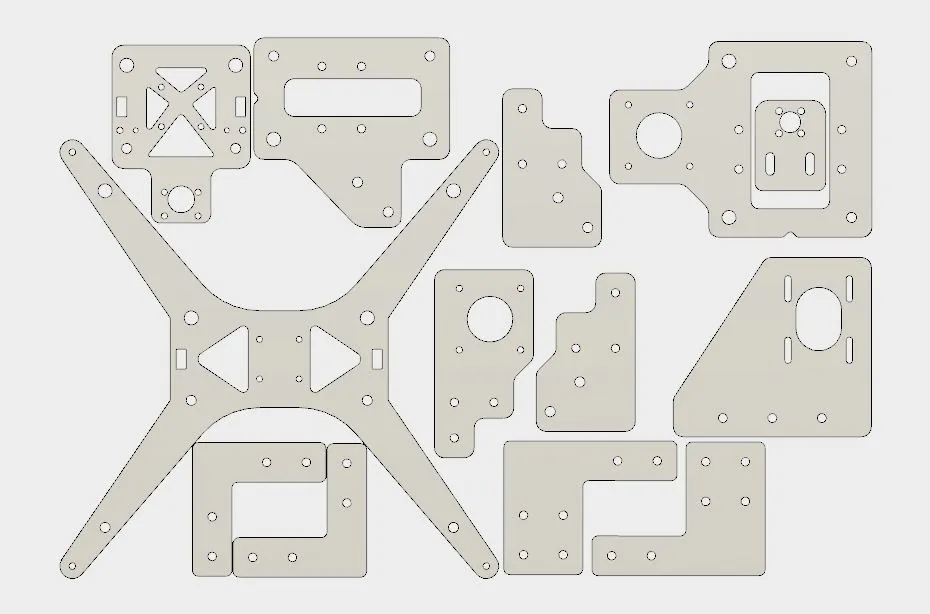

Top 5 Tevo Tarantula Acrylic Parts CAD Designs

Here are five of the most popular and beneficial acrylic parts CAD designs to elevate your Tevo Tarantula experience. These upgrades enhance functionality, improve aesthetics, and generally refine your 3D printing setup. Remember to assess your own needs and prioritize the upgrades that will bring the most value to your printer. Always check for reviews and make sure the design aligns with your specific printer model and any existing modifications you have.

Acrylic Frame Upgrades

A full acrylic frame replacement or reinforcement is a foundational upgrade. This replaces the original frame with a more robust and rigid structure. Such upgrades drastically reduce vibrations, improving print quality and accuracy. Look for designs that offer laser-cut precision and easy assembly. The increased stability is particularly noticeable when printing at higher speeds or with more challenging materials. Choose an acrylic frame upgrade for the most significant impact on your printer’s overall performance.

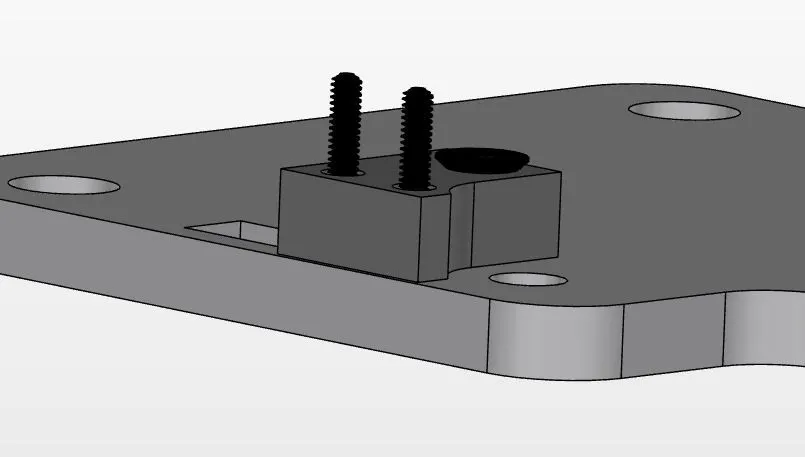

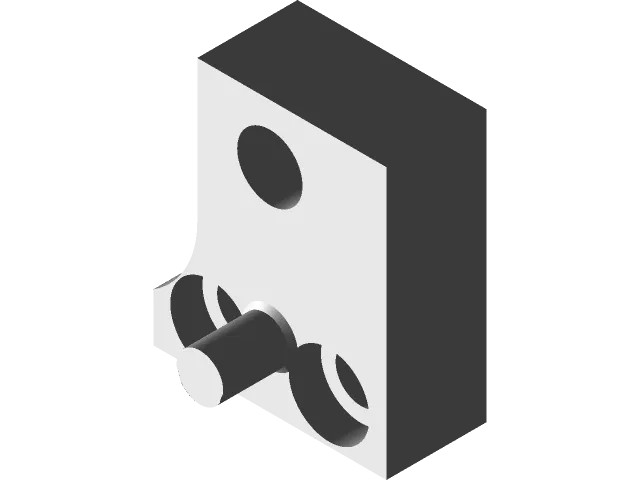

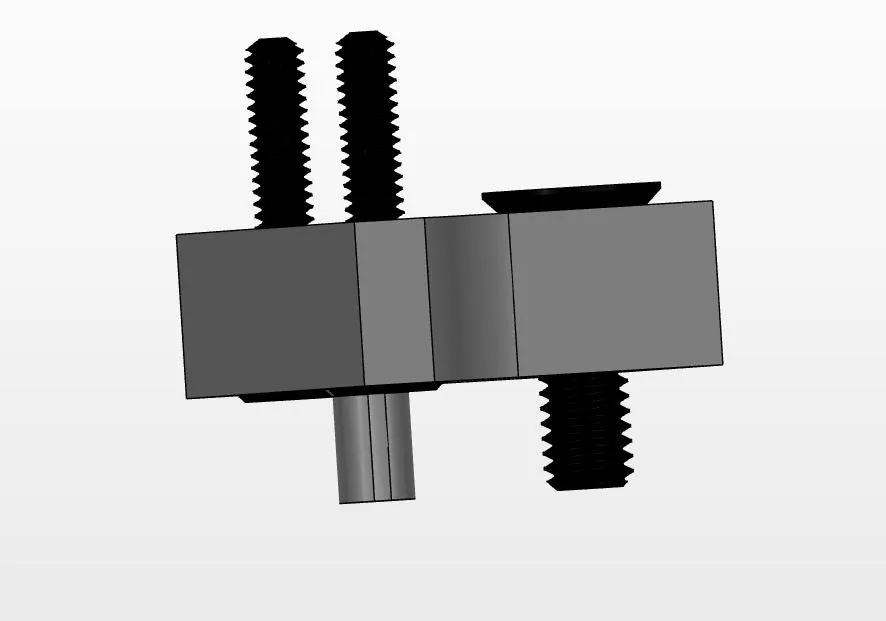

Bed Leveling Adjustment Knob

Improving the bed leveling process is crucial for successful prints. Replacing the original bed leveling screws with larger, easier-to-grip acrylic knobs simplifies this process. This modification provides more control and makes leveling the bed significantly more convenient. This is a simple but highly effective upgrade that enhances usability. This upgrade is crucial for achieving a properly leveled bed, which is the foundation of successful 3D printing. See image: bed-leveling-knob.webp.

Spool Holder Designs

An acrylic spool holder is a practical and aesthetically pleasing upgrade, offering several benefits. It organizes your filament spools, preventing tangles and improving the feeding of the filament to the extruder. Acrylic spool holders are designed to mount directly onto the printer’s frame, saving space and providing easy access to your filaments. They are available in various designs, from simple side-mounted holders to more elaborate setups with bearings for smoother filament feeding. This is a simple but effective upgrade that enhances the overall appearance and functionality of your Tevo Tarantula. See image: spool-holder.webp.

Electronics Enclosure

Protecting your printer’s electronics from dust, debris, and accidental damage is essential for longevity and reliability. An acrylic electronics enclosure provides a secure and organized space for the mainboard, power supply, and other sensitive components. Enclosures often include features like ventilation holes for cooling and access panels for easy maintenance. See image: electronics-enclosure.webp. An acrylic enclosure adds a professional touch to the printer and provides peace of mind.

Display Panel Upgrades

Upgrading the display panel with an acrylic enclosure or bezel not only improves the aesthetics but also protects the display screen from damage. These upgrades often feature a more streamlined design, integrating the display seamlessly into the printer’s frame. They can also include mounting options for control knobs and other accessories. See image: display-panel-upgrade.webp. A well-designed display panel upgrade enhances the overall visual appeal and user experience of the Tevo Tarantula.

How to Find and Download CAD Files

Finding the right CAD files is essential for creating acrylic parts for your Tevo Tarantula. Several online resources offer a vast library of designs. Platforms like Thingiverse and MyMiniFactory host numerous community-contributed designs, often available for free download. Search using relevant keywords such as “Tevo Tarantula acrylic parts” or “Tarantula upgrades.” When searching for CAD files, look for designs that are well-documented and have positive reviews from other users. Make sure the files are in a compatible format for your chosen 3D printing software. Consider the licensing of the files. Some designs are available under a Creative Commons license, allowing for modification and redistribution, while others are restricted.

Where to Source Tevo Tarantula Acrylic Parts CAD

Several online platforms and repositories are dedicated to hosting 3D model files. These platforms serve as central hubs for makers and designers to share their creations. Thingiverse is one of the largest and most popular repositories. It hosts a vast collection of designs, including a significant number of Tevo Tarantula acrylic parts. MyMiniFactory is another excellent resource, known for its curated selection of high-quality models. Cults3D is a marketplace where designers can sell their models, offering a wider variety of paid designs. You can search on these platforms for files that meet your needs. When choosing a source, consider the community feedback, the quality of the designs, and the licensing terms. Checking the user comments and ratings can help you gauge the quality and suitability of each design. Also, consider exploring specialized forums and online communities dedicated to the Tevo Tarantula, as they often share custom designs and modifications.

Websites and Repositories for CAD Files

Beyond the major platforms, there are many specialized websites and repositories. GitHub is a platform primarily for software development, but it also hosts CAD files, especially for open-source projects. GrabCAD is another professional platform offering a wide range of CAD models, including those for engineering and mechanical applications. Local 3D printing communities and maker spaces often share designs specific to their members. When looking for CAD files, always verify the file format and ensure that it is compatible with your 3D modeling software and printer. Look for files in commonly used formats such as STL, STEP, or DXF.

Tips for Selecting the Right CAD Files

Selecting the right CAD files involves several crucial considerations. First, ensure that the design is compatible with your specific Tevo Tarantula model. Versions and revisions of the Tarantula can vary, so double-check measurements and mounting points. Examine the design’s complexity and printability. Avoid files that are overly intricate or have delicate features, as these may be difficult to print accurately. Check the design’s resolution and scale. It is recommended to print a small test part before committing to a full-scale print. Study the reviews and comments from other users who have downloaded and printed the file. These insights can provide valuable information about printability, accuracy, and any potential issues. Consider the material specifications. Ensure that the CAD file is designed for use with acrylic and accounts for its properties, such as its tendency to warp if exposed to high temperatures.

Customizing Your Acrylic Parts

Customizing acrylic parts allows you to tailor your Tevo Tarantula to your specific needs. You can begin by modifying existing CAD designs using 3D modeling software like Fusion 360, Tinkercad, or FreeCAD. These programs let you adjust dimensions, add features, and personalize the parts to your liking. You can also design your own parts from scratch. This will require some basic knowledge of CAD software, but it gives you complete control over the design. When customizing, consider adding your logo, incorporating color schemes, or modifying the design to fit custom accessories. Always account for the printer’s mechanical limitations. Keep in mind the potential effects of material properties and temperature resistance. Before printing a complete custom part, test it by printing a small prototype to verify its fit and functionality. Experiment with different design elements to create unique and personalized upgrades for your Tevo Tarantula.

Modifying Existing CAD Designs

Modifying existing CAD designs is a great way to personalize your acrylic parts. Start by downloading the CAD file in a compatible format (STL, STEP, etc.). Then, import it into a 3D modeling software program. Use the software’s tools to make adjustments, such as changing the dimensions, adding features, or modifying the shape. Popular software options include Fusion 360 (powerful and versatile), Tinkercad (user-friendly, web-based), and FreeCAD (open-source). When modifying, ensure that your changes align with the printer’s capabilities and the properties of acrylic. For example, avoid adding features that are too small or complex for the printer to handle. Also, consider the potential impact of your modifications on the part’s structural integrity. Save your modified design in a new file to preserve the original. Before printing the final part, print a small test version to verify your changes.

Designing Your Own Acrylic Parts

Designing your own acrylic parts offers the ultimate level of customization. Begin by familiarizing yourself with CAD software. Learn the basics of 3D modeling, including sketching, extruding, and boolean operations. Consider the function and form of the part you want to create. Sketch your design and determine its key dimensions, mounting points, and features. Create a 3D model of your design using the CAD software. Pay close attention to detail and ensure your model is accurate and properly scaled. Include features that are necessary for assembly and functionality, such as holes, slots, and supports. To create accurate parts, consider the limitations of 3D printing. Design your part with appropriate clearances, tolerances, and supports. Export your finished design to an STL file. This file will be used for printing. Before printing, thoroughly test your design to verify fit and function.

Printing and Installing Acrylic Parts

Printing and installing acrylic parts requires careful attention to detail. Start by slicing your STL file in a 3D printing software, such as Cura or PrusaSlicer. Set the appropriate print settings. Pay close attention to the layer height, infill density, and support structures. High-quality prints are usually achieved with a lower layer height. Print the parts using a suitable 3D printing filament. Ensure your printer bed is level and that the nozzle is properly calibrated. Once the printing is complete, remove any support structures and clean up the printed parts. Assemble the parts according to the design. This may involve using screws, nuts, or other fasteners. Double-check all connections to ensure that they are secure. If necessary, trim or sand the parts to ensure that they fit properly. Take care to avoid damaging the parts during assembly. After installation, test the functionality of the upgraded components. Ensure that the printer is operating correctly.

Best Practices for 3D Printing Acrylic Parts

Achieving successful prints with acrylic parts requires careful attention to best practices. First, select a suitable 3D printing material. ABS is a common choice because it provides good mechanical properties, although PLA can also be used for less demanding applications. Adjust the printer settings according to the chosen material’s recommendations. Set the appropriate nozzle temperature, bed temperature, and print speed. Optimize the slicer settings to improve print quality. Use a low layer height to achieve fine details and a higher infill density to improve the parts’ strength. Implement proper bed adhesion to avoid warping. Use a heated bed and apply an adhesion aid, such as painter’s tape, to the build plate. Proper orientation is important when printing, particularly for complex designs. Position the part to minimize the need for supports and to optimize structural integrity. If supports are necessary, design them in a way that is easy to remove. Provide adequate cooling to minimize warping and improve dimensional accuracy. Ensure your printer is well-calibrated and maintained. Regularly check the nozzle, bed, and belts to ensure optimal performance. See image: tevo-tarantula-3d-printer.webp.

Assembly and Installation Guide

A successful acrylic part upgrade hinges on proper assembly and installation. First, gather all necessary tools and materials. This includes the printed acrylic parts, screws, nuts, wrenches, and any other required hardware. Study the design documentation. Familiarize yourself with the assembly instructions and identify any potential challenges. Prepare the printer for the upgrade. Disconnect power and, if necessary, remove any existing parts that will be replaced. Carefully align the acrylic parts according to the design instructions. Use screws, nuts, or other fasteners to secure the parts in place. Tighten the fasteners until they are snug, but avoid over-tightening, which can damage the acrylic. Check the alignment and fit of all installed parts. Ensure that everything is correctly positioned and that there are no gaps or misalignments. After installation, test the printer’s functionality. Verify that all moving parts are working smoothly and that there are no obstructions. See image: acrylic-frame-upgrade.webp.

Maintaining and Upgrading Your Tevo Tarantula

Regular maintenance and ongoing upgrades are essential for keeping your Tevo Tarantula in top condition. Clean and lubricate the printer’s moving parts regularly, such as the linear rods and belts. This will ensure smooth operation and prevent wear and tear. Regularly check and tighten all screws and fasteners to prevent vibrations and maintain accuracy. Keep the printer’s components clean, removing dust and debris that can interfere with printing. Periodically inspect the nozzle and hotend to ensure that they are functioning correctly and that there are no blockages. As new technologies and advancements emerge, consider implementing further upgrades. This might involve upgrading the firmware, installing a new controller board, or adding features. Keep your printer up to date with the latest software and firmware. Refer to online communities and forums. Stay informed about the latest tips, tricks, and maintenance practices to prolong the life of your printer.

Common Issues and Troubleshooting

Encountering issues is part of the 3D printing process, but proper troubleshooting can resolve many problems. Warping is a common issue, often caused by uneven cooling. Address this by using a heated bed, applying an adhesion aid, and adjusting the print settings. Layer separation can result from incorrect temperature settings, insufficient bed adhesion, or incorrect print speeds. Optimize the temperature, bed adhesion, and print speed to resolve this. Nozzle clogs can occur due to several reasons, including improper temperature, filament quality, and the presence of debris. Perform a cold pull, or use a needle to clean the nozzle. Ensure your nozzle is clean and your filament is free of debris. Poor print quality, such as stringing or rough surfaces, might be caused by incorrect temperature settings, print speeds, or retraction settings. Calibrate the printer and optimize your print settings. Check your belts and bearings for any wear.

Future Upgrades and Modifications

The Tevo Tarantula is a highly adaptable machine. Continuous upgrades and modifications can significantly improve its capabilities and functionality. Consider upgrading the printer’s mainboard to a more advanced model, offering features such as smoother motion control and greater processing power. Add a heated bed if you do not have one already. Consider adding a dual-extruder setup. Experiment with different nozzle types. Install a direct drive extruder for improved filament feeding and retraction control. Upgrade the power supply for greater reliability and safety. Explore the use of different filaments, such as PETG or nylon. Join online communities to connect with fellow enthusiasts and learn from their experiences. Stay informed about the latest advances in 3D printing technology. These are just a few ideas to help keep your Tevo Tarantula up-to-date and optimized.