What is the Tevo Tarantula Board Type

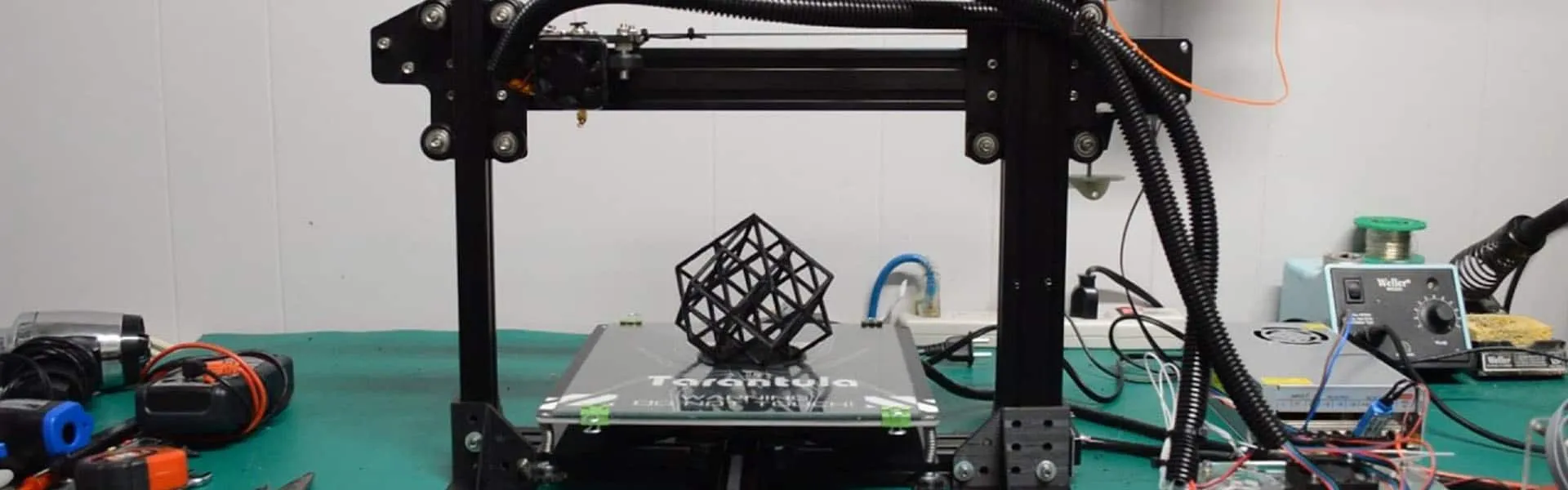

The Tevo Tarantula is a popular 3D printer known for its affordability and accessibility, making it a favorite among hobbyists and beginners. At the heart of this printer lies its control board, the brain that dictates all operations. The ‘board type’ refers to the specific electronic board used in the Tevo Tarantula, which determines the printer’s functionality, features, and capabilities. These boards are responsible for controlling the motors, heating the bed and nozzle, reading sensor data, and processing instructions from the user. Understanding the various board types is crucial for anyone looking to upgrade, troubleshoot, or simply get the most out of their Tevo Tarantula 3D printer. Different board types offer varying degrees of performance, ease of use, and expandability, impacting the overall 3D printing experience. This guide will delve into the essential aspects of Tevo Tarantula board types, providing insights into their characteristics and how to select the best one for your specific needs.

Understanding the Different Board Types

The control board in a 3D printer acts as the central processing unit, managing all the intricate operations required to bring a digital design into a physical object. Different board types offer unique features and capabilities. These boards come with their own set of firmware, which interprets the G-code instructions from the slicer software and translates them into the actions that the printer must take. Factors like the number of stepper motor drivers, the presence of features like thermal runaway protection, and the type of connectivity (USB, SD card, Wi-Fi) can vary significantly between board types. The choice of board type influences printing quality, speed, and the ability to add upgrades like auto-bed leveling or Wi-Fi connectivity. Therefore, understanding the differences among the various board types is critical for users to customize their printing experience.

Common Board Types Used

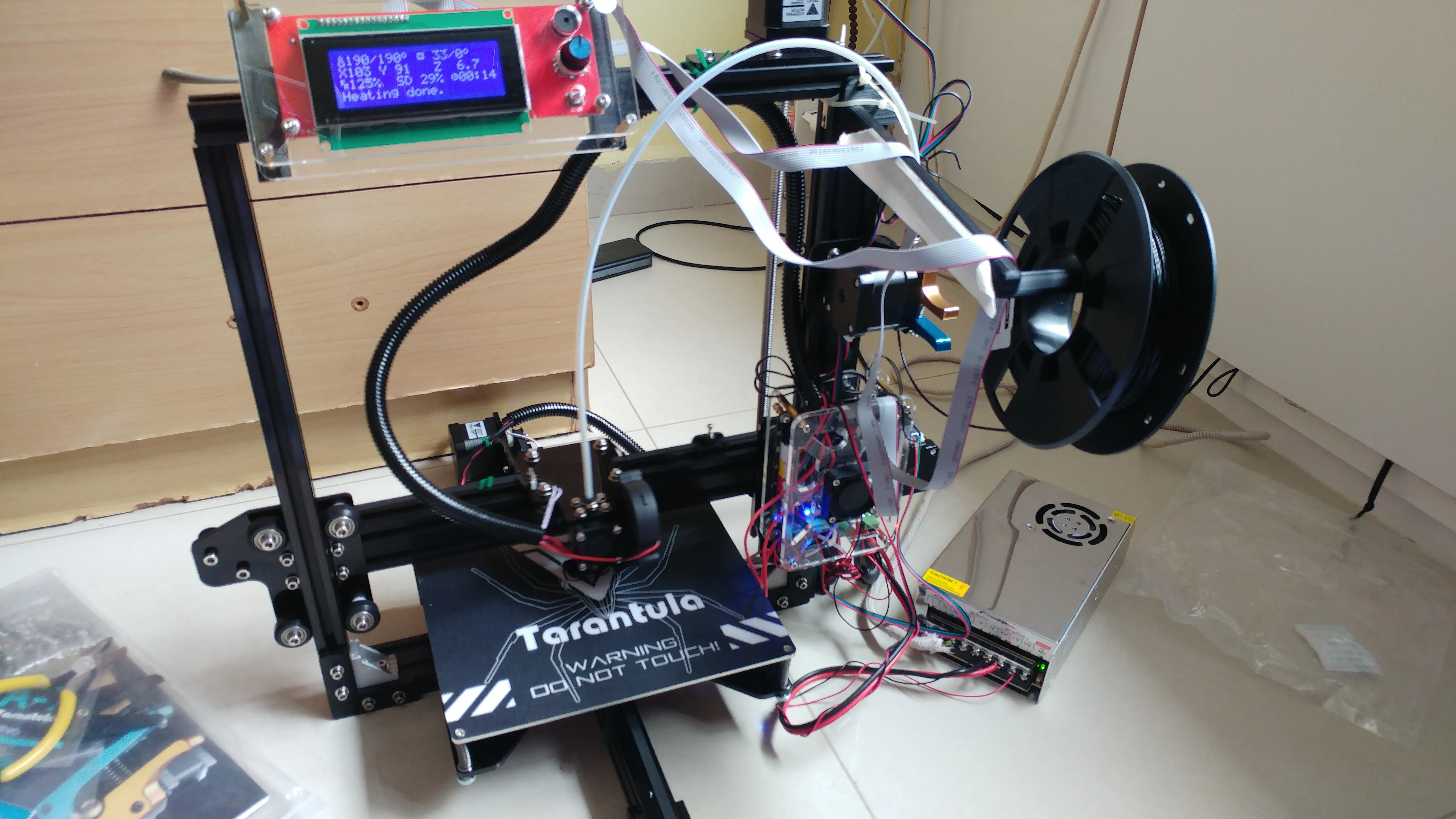

The Tevo Tarantula initially shipped with several board types, with the most common being the Melzi board. This board provided a basic, yet functional, platform for controlling the printer. As the 3D printing community evolved, so did the options for control boards. Another popular choice is the Arduino Mega 2560, often paired with a RAMPS (RepRap Arduino Mega Pololu Shield) for additional features. These setups are highly customizable, allowing users to upgrade and modify their printers extensively. More advanced options include boards like the SKR Mini E3 series, which offer enhanced processing power, quieter stepper motor drivers, and features like auto-bed leveling support directly integrated into the board. The variety of options means users can tailor their board type to suit their specific needs, whether it be for basic printing, high-quality prints, or advanced projects. The image below shows a variety of boards to give a better understanding on the options available.

Board Type Characteristics

The characteristics of a 3D printer control board are critical factors that determine the functionality, reliability, and upgrade potential of the Tevo Tarantula. Key specifications to consider include the microcontroller, the number of stepper motor drivers, the type of connectivity, and the firmware capabilities. The microcontroller is the brain of the board, and its processing power affects the speed and efficiency of print operations. The number of stepper motor drivers determines how many axes the printer can control independently, influencing the complexity of models it can print. Connectivity options, such as USB and SD card slots, affect how easily you can transfer files to the printer. Firmware capabilities, such as support for features like thermal runaway protection and auto-bed leveling, significantly impact safety and ease of use. Understanding these characteristics empowers users to select a board that optimally meets their printing requirements, improving both performance and user experience.

Top 5 Facts About Tevo Tarantula Board Types

Fact 1 Stability and Durability

Stability and durability are essential characteristics of a reliable Tevo Tarantula board type, directly impacting the longevity and consistency of the printer. The board’s construction quality, including the components used and the layout design, significantly affects its operational life. A well-built board will have robust connections, high-quality components that can withstand heat and voltage fluctuations, and proper protection mechanisms such as fuses and voltage regulators. Boards known for their stability often feature enhanced thermal management systems, such as heat sinks, which dissipate heat more efficiently, preventing overheating. Durability is further enhanced by implementing robust firmware with features like thermal runaway protection, preventing dangerous temperature spikes that could damage the printer or pose safety hazards. These features help ensure that the printer operates safely and reliably over extended periods, minimizing the need for frequent repairs or replacements.

Fact 2 Connectivity and Features

The connectivity and features of a Tevo Tarantula board type significantly influence its usability and the user’s overall printing experience. Connectivity options like USB ports, SD card slots, and Wi-Fi capabilities determine how files are transferred to the printer and the ease with which it can be controlled. USB connectivity allows for direct communication with a computer for real-time monitoring and control, while SD card slots provide a convenient way to print from pre-loaded files. Wi-Fi functionality enables wireless file transfer and remote printer management, adding considerable convenience. Beyond basic connectivity, modern boards often include advanced features such as support for auto-bed leveling, which simplifies the calibration process, and multiple driver support, allowing for more complex prints. The inclusion of features like touchscreen interfaces and the ability to connect to external sensors enhances the printer’s functionality and usability, streamlining the 3D printing workflow and making the process more user-friendly and efficient.

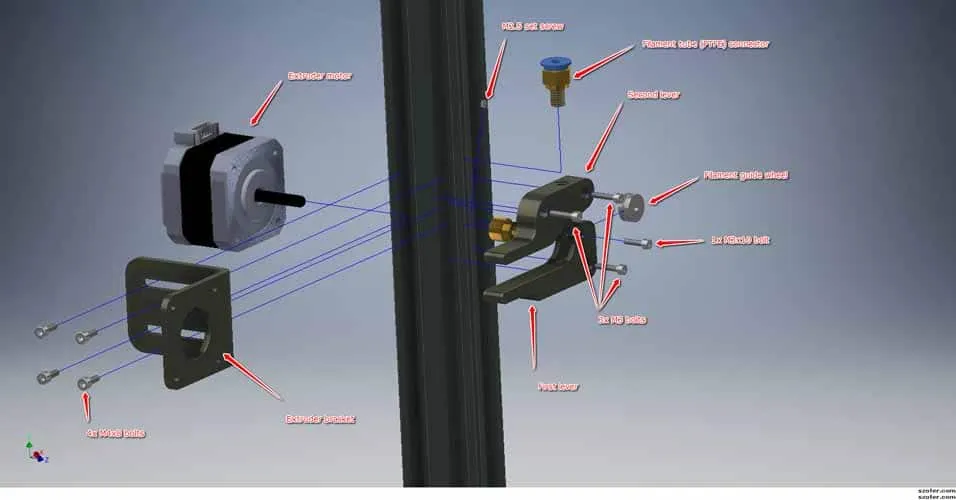

Fact 3 Compatibility and Upgradability

Compatibility and upgradability are important factors for Tevo Tarantula board types. Compatibility ensures that the board can work seamlessly with existing hardware and software, while upgradability allows for future enhancements. Compatibility includes the ability of the board to interact with the existing motors, sensors, and other components of the Tevo Tarantula. It also involves supporting different firmware and slicer software. The board’s pinouts and connectors should match those of the printer for easy integration. Upgradability refers to the board’s capacity to accommodate improvements. Boards that support upgrades include features like additional stepper motor drivers, which allow for more advanced print capabilities. They also often allow for firmware updates, which can bring performance improvements and the latest features. For example, the board should have the capacity to add new sensors or features like auto-bed leveling, or integrate with accessories. The image below shows an example of an upgraded board.

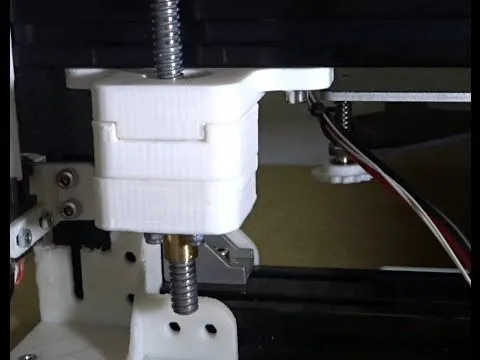

Fact 4 Ease of Use and Installation

Ease of use and installation are essential considerations for any Tevo Tarantula board type, especially for users with limited technical expertise. A user-friendly board should come with clear documentation and straightforward instructions. Installation typically involves physically mounting the board in the printer and connecting the various components, such as motors, heaters, and sensors. Boards designed for ease of use often feature clearly labeled connectors and user-friendly firmware, allowing for easier setup and configuration. Well-designed boards minimize the need for complex wiring or soldering, reducing the risk of errors during installation. Firmware that is easy to flash and configure simplifies setup, enabling users to quickly get their printer up and running. The overall experience is enhanced by intuitive software and clear guides. An image of a board installation can be very helpful.

Fact 5 Performance and Printing Quality

The performance and printing quality of a Tevo Tarantula are directly affected by the board type. A high-performance board ensures precise control over the printer’s motors, heaters, and other components, which leads to better print results. Factors such as the microcontroller’s processing speed, the quality of the stepper motor drivers, and the firmware’s algorithms all contribute to the overall printing quality. Faster processing speeds allow the printer to execute instructions more quickly, reducing printing times and enhancing precision. Higher-quality motor drivers ensure smoother, more accurate movements. Firmware with features like advanced motion control and thermal management can significantly improve the overall print quality and consistency. The board must provide accurate temperature control to ensure proper layer adhesion and the prevention of warping or other print defects. Ultimately, the board type plays a critical role in determining the final quality and performance of the printed objects.

Choosing the Right Board Type for Your Needs

Selecting the appropriate board type for a Tevo Tarantula depends on individual needs and goals. The choice of a board should be based on factors such as skill level, desired features, and budget constraints. Beginners might prefer boards that are simple to install and configure, with straightforward documentation. Experienced users who are looking for more control and advanced features could find boards with upgraded processors, support for auto-bed leveling, or more complex configurations. The user needs to consider whether the board needs to accommodate upgrades, such as dual extruders or Wi-Fi connectivity. The goal should be to strike a balance between cost and functionality, ensuring that the chosen board meets current printing requirements while allowing for future expansions. Carefully evaluating these factors ensures the selected board not only meets present needs but also provides scope for future upgrades. The image below provides a comparison of board options.

Factors to Consider

When choosing a Tevo Tarantula board type, several factors need careful consideration. The first is the processing power of the board, which determines the speed and efficiency of printing. High-performance boards, with faster microcontrollers, can handle complex print jobs. The second factor is the number of stepper motor drivers, which should match the printer’s configuration. Third, assess connectivity options, such as USB, SD card, and Wi-Fi. Consider any special features, such as support for auto-bed leveling and thermal runaway protection. Finally, determine the level of support and community resources available for the board, which can be very helpful. The image below shows all the factors in a list for easy reference.

Cost and Budget

The cost and budget are important factors in deciding on a Tevo Tarantula board type. Boards are available across a wide price range, with the cost often corresponding to the features and capabilities they offer. Basic boards, like the Melzi, offer a cost-effective entry point. Mid-range boards, like the Arduino Mega, typically include additional features and increased processing power. High-end boards, with advanced features like multiple motor drivers, Wi-Fi connectivity, and improved thermal management, come at a higher price point. It’s essential to align the board selection with your budget, ensuring the chosen option includes the essential features. A well-planned budget will help avoid overspending while providing a reasonable quality print experience. Consider not only the initial cost but also any associated expenses, such as the cost of additional parts or upgrades.

Upgrading Your Tevo Tarantula Board Type

Upgrading the Tevo Tarantula board type is a common way to improve print quality, expand functionality, and extend the printer’s lifespan. Before upgrading, it’s essential to determine the current board’s specifications and the desired improvements. This allows you to select a board that meets the needs. Preparation for the upgrade includes gathering all the necessary tools and materials, such as screwdrivers, wire strippers, and any required mounting hardware. The installation process generally involves removing the old board, carefully disconnecting and reconnecting all the wiring to the new board. Ensure that all connections are secure and that the wiring follows the correct pin assignments. After the physical installation, you’ll need to flash the firmware onto the new board, which configures the printer for the specific hardware. This is where you will need to configure settings such as motor current, thermistor type and bed size. The benefits of upgrading can include improved print quality, faster print speeds, added features, and greater ease of use. With careful planning and execution, an upgrade can significantly enhance the capabilities and user experience of the Tevo Tarantula 3D printer.