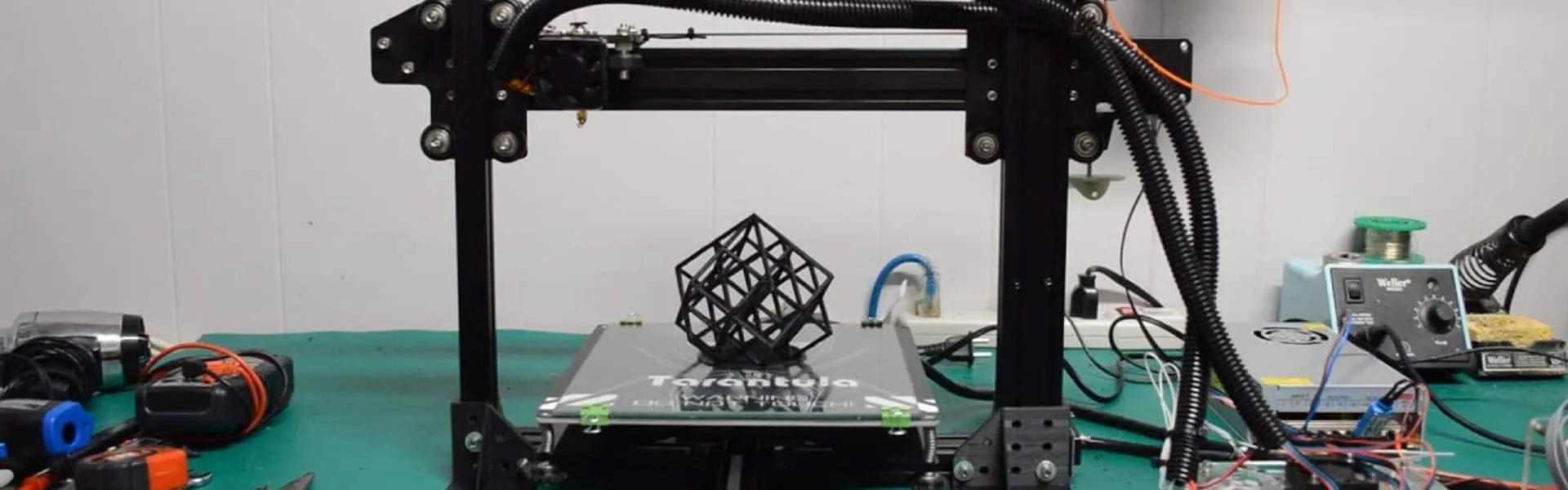

Understanding Tevo Tarantula Calibration

Calibration is a critical process for any 3D printer, and the Tevo Tarantula is no exception. It’s the key to achieving high-quality prints with accurate dimensions, proper layer adhesion, and minimal defects. Proper calibration ensures that your printer operates at its best, transforming digital designs into physical objects that match your expectations. This means fine-tuning various aspects of your printer, from the bed level to the extruder settings and temperature parameters. By investing time in calibration, you’re setting the stage for successful 3D printing, saving time, material, and frustration in the long run.

Why Calibration Matters for Your Tevo Tarantula

Calibration is not just a one-time task, but an ongoing process that helps to ensure optimal performance and consistent print quality. Without it, you might encounter issues like poor bed adhesion, warped prints, incorrect dimensions, stringing, and layer separation. These problems can stem from misaligned axes, incorrect nozzle temperatures, or improperly calibrated extrusion. The Tevo Tarantula, like many 3D printers, has several adjustable components and settings, and these need to be correctly configured to produce reliable and accurate 3D prints. A well-calibrated Tevo Tarantula leads to more successful prints, allowing you to fully realize the potential of your 3D printer.

Common Calibration Issues

Several common issues can arise when your Tevo Tarantula is not properly calibrated. Bed leveling problems lead to the nozzle being too close or too far from the print bed, resulting in poor first-layer adhesion. Incorrect Z-offset settings also contribute to adhesion problems or, conversely, nozzle scraping on the bed. Extruder calibration errors result in under- or over-extrusion, causing weak layers or excessive filament deposition. Temperature inconsistencies affect how the filament melts and bonds, leading to poor layer adhesion and warping. Ignoring these issues can lead to print failures, material waste, and frustration. Regular calibration is essential to identifying and correcting these problems promptly.

Top 5 Tevo Tarantula Calibration Tips

Leveling the Bed

Bed leveling is perhaps the most critical step in Tevo Tarantula calibration. A level bed ensures that the first layer of your print adheres properly. If the bed is not level, the nozzle may be too far from the bed in some areas and too close in others. This leads to adhesion problems. You can level the bed by manually adjusting the bed-leveling screws at each corner while the nozzle is heated to the correct printing temperature. A piece of paper can be used to gauge the distance between the nozzle and the bed, ensuring that there is slight resistance when the paper is moved. The goal is to achieve consistent nozzle-to-bed distance across the entire surface of the bed. Repeat this process until the bed is level.

Manual Bed Leveling

Manual bed leveling involves physically adjusting the four leveling screws located under the print bed. Preheat the nozzle and bed to the printing temperatures for your chosen filament. Move the nozzle to each corner of the bed, and use a piece of paper to check the gap between the nozzle and the bed. Adjust the leveling screws at each corner until the paper has slight resistance when pulled. Repeat this process, going around the bed several times, until the nozzle height is consistent across the entire bed surface. Ensure you’re leveling at printing temperatures to account for thermal expansion of the components. This ensures that the bed is as flat as possible when printing.

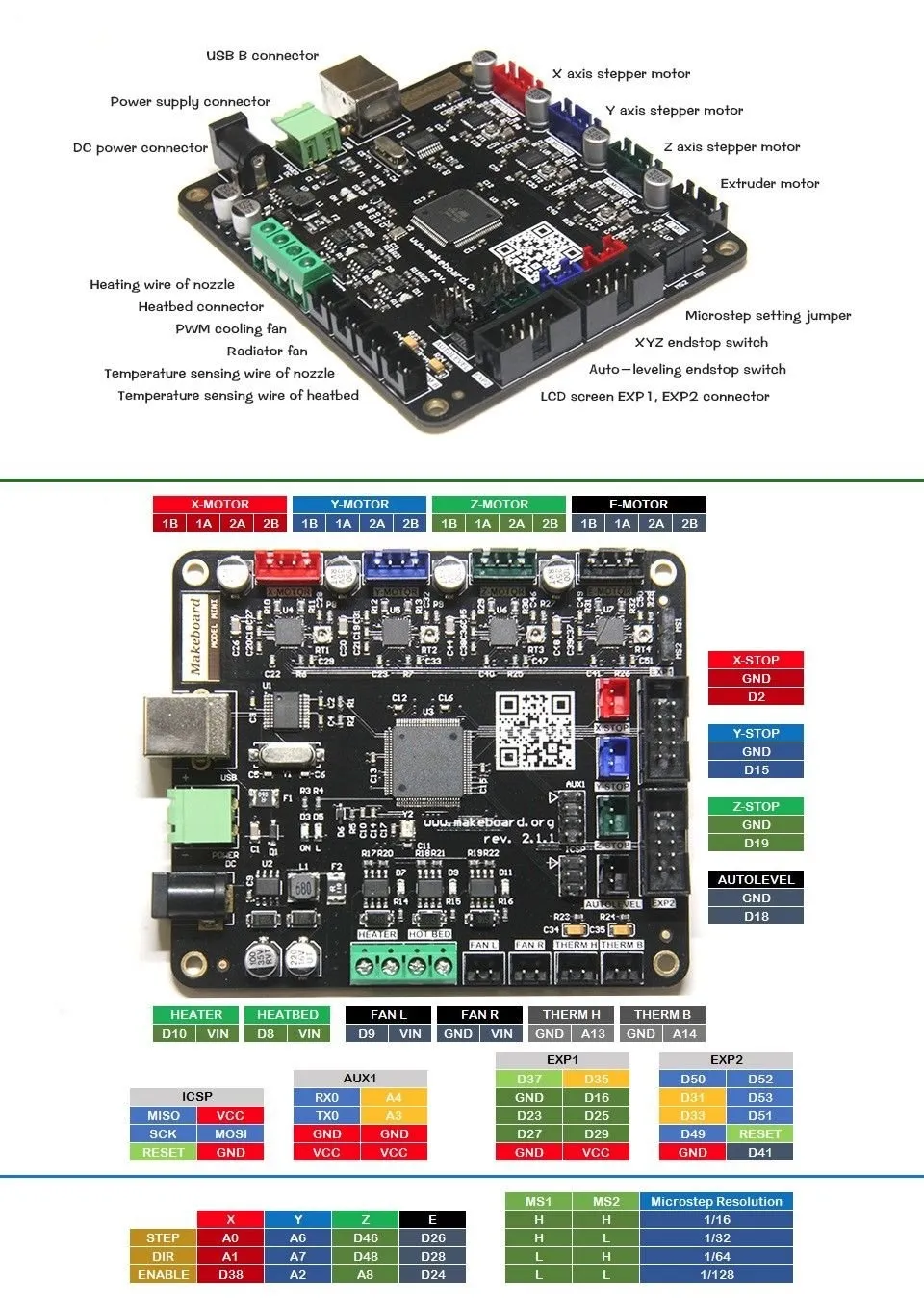

Using Auto Bed Leveling (If Equipped)

If your Tevo Tarantula has auto bed leveling (ABL), the process is simplified. Ensure the ABL sensor is correctly positioned and connected to the printer’s control board. After preheating, the ABL sensor will probe the bed at multiple points to determine the bed’s surface. This information is used to compensate for any imperfections in the bed’s flatness during printing. In the printer’s firmware, you must enable ABL and set the correct Z-offset to ensure the nozzle is at the correct distance from the bed. Check that the ABL system is functioning properly by observing its probing behavior and verifying that the first layer prints correctly. Then the printer will automatically adjust the nozzle height as it moves across the bed.

Adjusting Z-Offset

The Z-offset is the distance between the nozzle and the print bed when the printer is at the Z=0 position. It’s critical for correct first-layer adhesion. If the Z-offset is too high, the filament won’t stick to the bed. If it’s too low, the nozzle will scrape the bed. To adjust the Z-offset, heat the nozzle and bed and then move the nozzle to the center of the bed. Use the printer’s control panel to slowly lower the nozzle towards the bed. While it moves down, watch the first layer to ensure the filament is correctly squished onto the bed surface. The correct offset will vary based on filament and bed surface, so minor adjustments are often necessary to fine-tune the first layer. The perfect setting should have the filament slightly squished, but not so much that it clogs the nozzle.

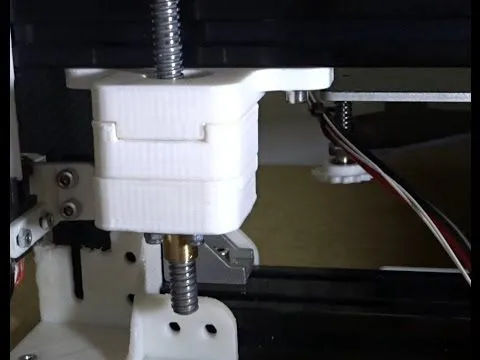

Calibrating the Extruder

Extruder calibration ensures that the correct amount of filament is fed to the hotend, thus maintaining the desired layer height and print dimensions. Two key adjustments here are the E-steps calibration and extrusion multiplier. E-steps calibrate the number of steps the extruder motor takes to push a certain length of filament. The extrusion multiplier helps fine-tune the amount of filament extruded to account for variations in filament diameter and other factors. Incorrect extruder calibration can lead to over- or under-extrusion, which compromises the print’s structural integrity and appearance. Therefore, it is important to perform both of these adjustments accurately.

E-Steps Calibration

E-steps per millimeter (E-steps/mm) calibration determines how much filament the extruder pushes through the nozzle. You will need a ruler, a marker, and a pair of calipers for this. First, heat the hotend to the appropriate temperature for your filament and mark a point 120 mm away from the extruder entry point on the filament. Next, disable the stepper motor, and then manually push the filament. Then, command the extruder to push 100mm of filament through the nozzle, but do not let it flow. Measure how much filament has been pushed, and use this value to recalculate your E-steps/mm setting. Adjust the E-steps setting in your printer’s firmware or control panel and test the calibration again. Repeat this process until the extruder is calibrated.

Extrusion Multiplier Adjustment

The extrusion multiplier fine-tunes the amount of filament extruded, accounting for variations in filament diameter. Print a single-walled test cube with a known wall thickness. Use calipers to measure the actual wall thickness. Compare the actual wall thickness to the expected value. Adjust the extrusion multiplier in your slicer to compensate for any differences. If the wall thickness is too thin, increase the extrusion multiplier. If the wall thickness is too thick, decrease the extrusion multiplier. Make minor adjustments and reprint the test cube until the measured wall thickness matches the expected thickness. This calibration step ensures the right amount of filament is deposited, improving the precision of your prints.

Temperature Calibration

Temperature calibration involves fine-tuning the hotend and bed temperatures. The correct temperatures are essential for proper filament melting, layer adhesion, and overall print quality. If the hotend temperature is too low, the filament may not melt properly, resulting in under-extrusion and weak layers. If it’s too high, the filament may overheat, causing oozing, stringing, and a loss of dimensional accuracy. Bed temperature is important for initial layer adhesion and preventing warping. The optimal temperatures depend on the filament type, and the printer’s specifications, and the ambient environment. It is very important to conduct temperature tests and find the best settings for the filament you are printing with.

Hotend Temperature Calibration

The hotend temperature affects how well the filament melts and bonds to the previous layer. Conduct a temperature tower test to determine the optimal hotend temperature for your filament. A temperature tower is a print that varies the hotend temperature over its height. Print the tower and inspect it for signs of under-extrusion, stringing, and poor layer adhesion. The ideal temperature is where the print has the best layer adhesion, no stringing, and smooth surface quality. Print a small temperature test to check the temperature’s efficiency and its potential effect on the quality of the prints. Make sure the temperature is consistent and the filament is melting properly, as well as adjust as needed.

Bed Temperature Calibration

The bed temperature is critical for ensuring that the initial layers stick to the bed and prevents warping. Test bed temperatures by printing a small test print, such as a square or a circle, with a brim. Start with the recommended bed temperature for your filament type. If the print does not adhere to the bed, increase the bed temperature in increments of 5°C. If the corners of the print start to lift, the bed temperature may be too high, so decrease it in small increments. Find the lowest bed temperature that provides adequate bed adhesion and prevents warping. The correct bed temperature ensures good adhesion and minimizes the risk of warping.

Fine-Tuning and Troubleshooting

Recognizing Calibration Problems

Learning to recognize calibration problems is essential for producing high-quality prints. Watch for common issues such as the first layer not sticking to the bed, which indicates bed leveling or Z-offset problems. Observe any warping or corners lifting off the bed, which suggests incorrect bed temperature. Examine prints for under-extrusion (gaps between layers) and over-extrusion (blobs and inconsistencies), indicating extruder calibration issues. Be alert for stringing and oozing, which can be caused by incorrect hotend temperatures or retraction settings. By carefully examining your prints, you can quickly identify calibration issues and take corrective action to produce better results.

Troubleshooting Common Issues

When troubleshooting calibration problems, start with the basics. Verify the bed is level and the Z-offset is correct. Ensure the extruder is properly calibrated and extruding the correct amount of filament. Check that your hotend and bed temperatures are suitable for the filament and environmental conditions. If you have adhesion problems, clean your print bed and possibly use an adhesive. For stringing issues, adjust retraction settings. For warping, try a brim or a heated enclosure. By systematically addressing these issues and making small adjustments, you can resolve most common calibration problems and achieve great results with your Tevo Tarantula.

Calibration is a continuous process that requires patience and attention to detail. However, the effort spent calibrating your Tevo Tarantula will pay off in the form of higher-quality prints, reduced material waste, and a more satisfying 3D printing experience.