Tevo Tarantula LCD Upgrades

The Tevo Tarantula 3D printer, a popular choice among hobbyists, offers a solid foundation for 3D printing. However, like any entry-level machine, there’s always room for improvement. One area where you can significantly enhance your printing experience is with upgrades to your Tevo Tarantula LCD. These upgrades not only improve the user experience but can also boost print quality and reliability. This guide explores five fantastic upgrades that will take your Tevo Tarantula to the next level, making your 3D printing journey more enjoyable and successful. Whether you are a beginner or an experienced user, these modifications are designed to be accessible and impactful.

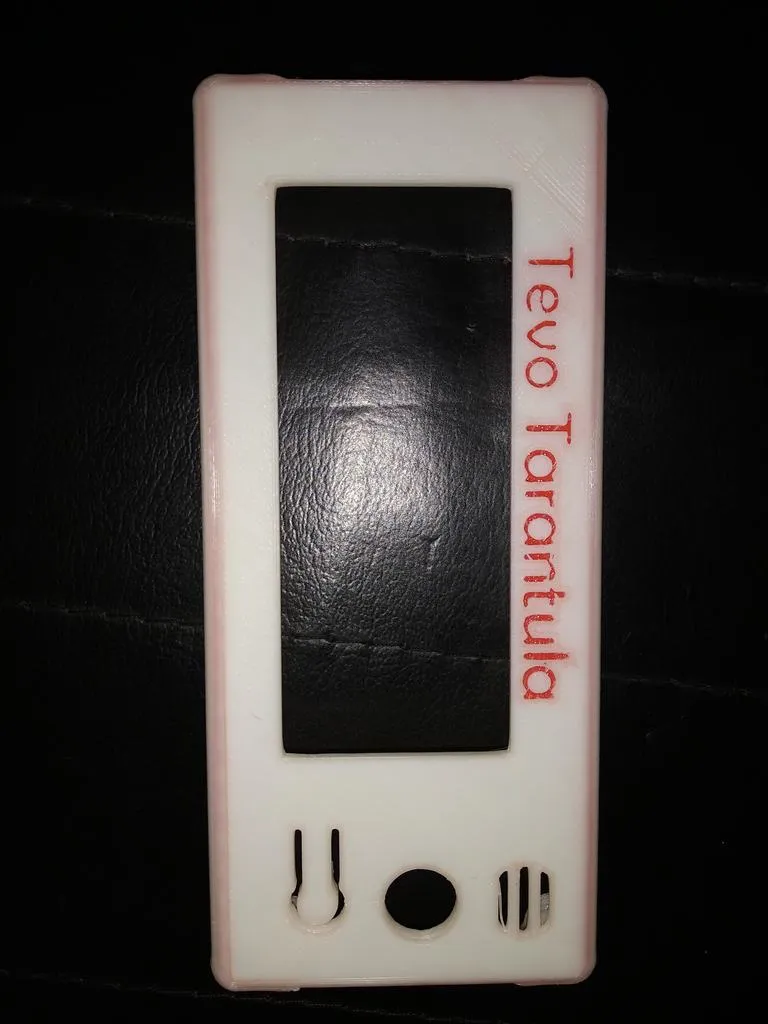

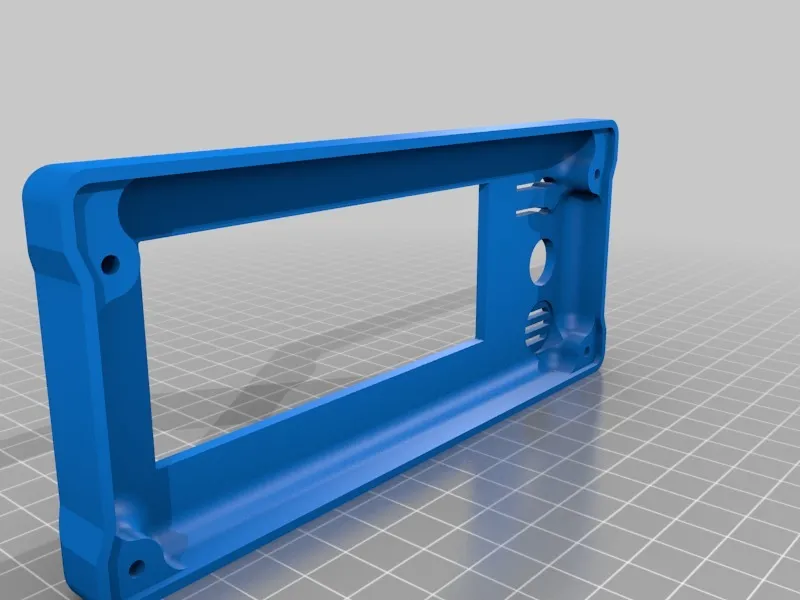

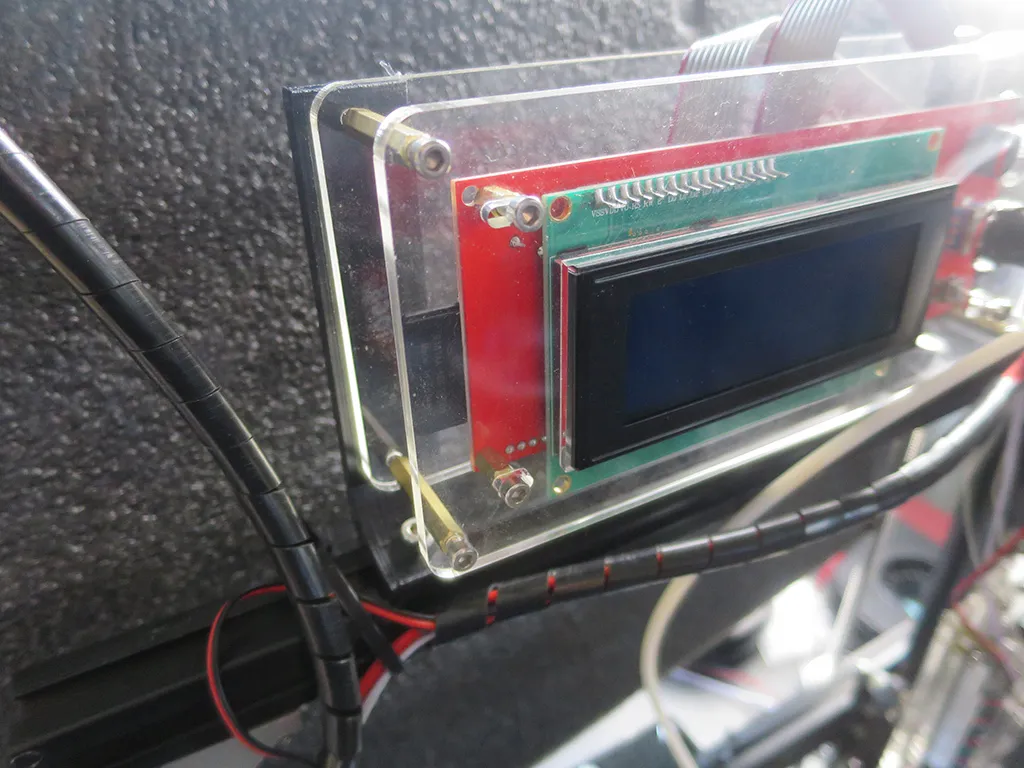

Upgrade 1 Enhanced Display

The stock LCD screen on the Tevo Tarantula, while functional, can be a limiting factor in terms of usability. Upgrading to a larger, higher-resolution display, or even a touchscreen, can drastically improve your interaction with the printer. This upgrade makes it easier to navigate menus, monitor print progress, and make adjustments on the fly. A clear and responsive display can save you time and frustration during the printing process, making the entire experience more streamlined. Furthermore, some aftermarket displays offer improved contrast and viewing angles, enhancing readability from various positions.

Why Upgrade Your LCD Screen

Upgrading the LCD screen is about more than just aesthetics. It’s about improving the overall usability of your 3D printer. A better screen offers a more intuitive interface, allowing you to quickly access important information like print temperature, bed temperature, and print progress. It also often comes with improved responsiveness, reducing lag and making it easier to control your printer. A modern display can also support features like SD card browsing and advanced control options, giving you more control over your prints.

Benefits of a Better Display

The benefits of a better display extend beyond convenience. A higher-quality screen reduces eye strain, especially during longer print jobs. Many upgraded screens offer better contrast and brightness, making it easier to see the details of the printer’s settings and the progress of your print. Some also incorporate touch screen functionality, which provides a more interactive and responsive control interface. The enhanced display helps to improve the overall print quality by giving you more control over your prints.

Upgrade 2 Control Board Enhancements

The heart of your Tevo Tarantula is its control board. Upgrading this component can unlock significant performance gains. Newer control boards often feature more powerful processors, leading to faster processing speeds and improved print quality. This upgrade can also open the door to advanced features and improved firmware compatibility, making your printer more versatile and easier to use. Upgrading the control board is an investment in your printer’s long-term performance, providing a foundation for future upgrades and enhancements.

Improving Firmware Compatibility

Upgrading your control board can unlock new firmware compatibility, enabling access to more advanced features and performance enhancements. Newer boards support updated versions of Marlin or other firmware, providing access to features like linear advance, which minimizes blobbing and improves the consistency of your prints. Improved firmware compatibility will often solve old problems, offering improved print quality. Compatible firmware will have a more modern, user-friendly interface. Firmware improvements are important as your skill grows, and you will need a solid board to support those advancements.

Boosting Processing Power

A more powerful control board translates directly to faster processing speeds. Faster processing means the printer can react more quickly to commands, resulting in improved print quality, especially at higher speeds. It also allows for smoother operation, reducing the likelihood of print errors and improving the accuracy of your prints. This faster processing power can make the difference between a good print and a great print, allowing for more complex models and detailed designs.

Upgrade 3 Filament Runout Sensor

One of the most frustrating experiences in 3D printing is running out of filament mid-print. A filament runout sensor will detect when your filament spool is empty and automatically pause the print. This prevents print failures and saves valuable time and material. Adding a filament runout sensor can be a simple but incredibly effective upgrade, improving the reliability of your printer. It ensures that your prints will be completed successfully, reducing the need to start prints over or manage your print spool.

Preventing Print Failures

The primary benefit of a filament runout sensor is preventing print failures. This small addition saves material and time. It is simple to add to your printer. It detects when the filament is empty. By pausing the print, the sensor allows you to replace the spool before the print fails, which is an invaluable feature for larger or more complex prints. It safeguards your work and investment in filament. A filament runout sensor ensures prints are more reliable.

Easy Installation Guide

Most filament runout sensors are easy to install and integrate with your existing Tevo Tarantula setup. They typically connect to the control board and are configured in the firmware. Installation usually involves connecting the sensor to the control board and then updating the firmware to recognize the sensor. Detailed guides and tutorials are readily available online, making the installation process straightforward. Some sensors are plug-and-play, simplifying the installation even further, and reducing complexity.

Upgrade 4 Auto Bed Leveling

Achieving a perfectly level print bed can be a challenge, but auto bed leveling (ABL) simplifies the process. ABL systems use a sensor to map the bed’s surface and automatically adjust the nozzle height during printing. This ensures the first layer adheres properly, which is crucial for a successful print. Auto bed leveling greatly reduces the time spent manually leveling the bed, and improves the consistency of prints. It’s a valuable upgrade for both beginners and experienced users.

Calibration Made Simple

Auto bed leveling systems simplify the calibration process. After installation, the printer automatically maps the print bed, compensating for any imperfections or unevenness. This automated process takes the guesswork out of bed leveling, ensuring a consistent first layer. Calibration is done automatically before each print, or as needed, ensuring prints adhere well. Auto bed leveling streamlines the printing process and reduces the need for manual adjustments.

Consistent First Layers

A consistent first layer is the foundation for a successful 3D print. Auto bed leveling systems guarantee consistent first layers by adjusting the nozzle height to the bed’s surface. This ensures the filament adheres properly and the print starts smoothly. With auto bed leveling, you’ll experience fewer failed prints, and better overall print quality. Consistently level beds mean increased reliability and quality.

Upgrade 5 Direct Drive Extruder

The direct drive extruder is a significant upgrade that moves the extruder motor closer to the hotend. This configuration offers improved filament control, allowing for greater precision and the ability to print with a wider range of materials, including flexible filaments. The direct drive setup reduces the distance filament must travel, minimizing the chance of issues like stringing and under-extrusion. This improves the printer’s performance and the quality of the prints.

Improved Filament Control

The primary benefit of a direct drive extruder is improved filament control. By reducing the distance the filament travels between the extruder and the hotend, this upgrade provides more responsive and accurate extrusion. This leads to fewer printing problems, increased accuracy, and a wider variety of materials you can print. Enhanced filament control means better print quality.

Print Quality Enhancement

A direct drive extruder significantly enhances the print quality, producing more detailed and precise prints. The improved control over filament extrusion minimizes issues like stringing, oozing, and under-extrusion, all of which are common problems. The direct drive system allows for better handling of flexible filaments. With a direct drive extruder, you can expect smoother surfaces, cleaner details, and higher-quality prints overall. Your print results are improved significantly.

Conclusion

Upgrading your Tevo Tarantula LCD can dramatically improve your 3D printing experience. From enhanced display options and control board upgrades to filament runout sensors, auto bed leveling, and direct drive extruders, there are many ways to boost performance. Each upgrade offers unique benefits, from improved usability and print quality to greater reliability and material compatibility. By implementing these five upgrades, you can unlock the full potential of your Tevo Tarantula and enjoy a more rewarding 3D printing journey. These upgrades allow you to customize your printer and enhance your printing results.